Plastic Molding

Achieve a hollow package that meets your requirements and functions with PLAPACS®

Our in-house design allows us to flexibly meet the needs of our customers.

Resin design: We offer the optimal resin for the product through the in-house design.

Product design: We realize the design of products with high efficiency and high quality in cooperation with the in-house design of molding dies.

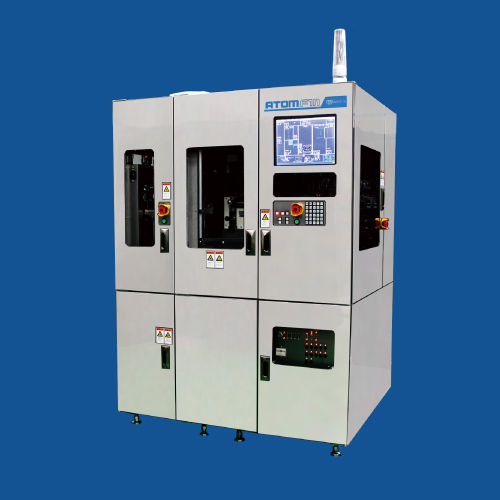

Production equipment: We are in-house developing efficient dedicated equipment.

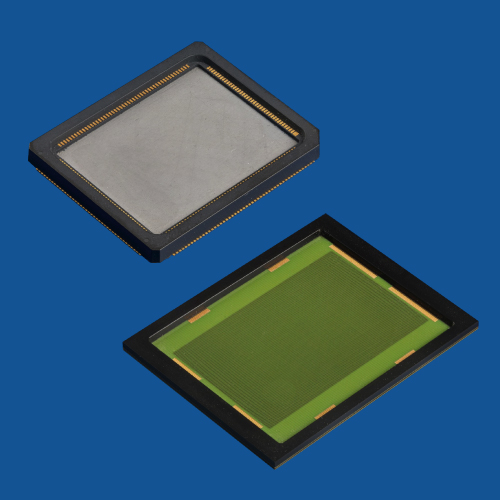

What is PLAPACS®

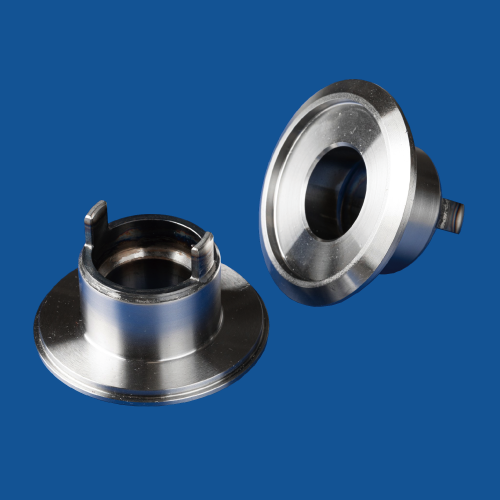

PLAPACS® is a plastic cavity package suitable for CCD/CMOS image sensors and other sensors. PLAPACS® has high dimensional precision and high humidity resistance by our unique epoxy resin compound and technology for composite metal and material.

- High dimensional precision

- High humidity resistance

- Low cost

- Lightweight

Feature of PLAPACS®

・High dimensional precision & Lightweight

Using our resin-design and transfer-molding technology, we achieve drastically accurate dimensions.

| Dimensional Items | PLAPACS®(Large) | PLAPACS®(Small, 1/3") | Ceramics(An Example) |

| Outside Dimensional Tolerance | ±50µm | ±30µm | ±50-200µm |

| Thickness Tolerance | ±30µm | ±25µm | ±30-150µm |

| Flatness of Seal Area | ≤50µm | ≤15µm | |

| Flatness of Die Attach Area | ≤50µm | ≤10µm | |

| Parallelism of Seal Area | ≤50µm | ≤15µm | |

| Parallelism of Die Attach Area | ≤50µm | ≤10µm | |

| Mass | 0.72g (1/3″) 1.70g (1/2″) | 1.56g (1/3″) 2.13g (1/2″) |

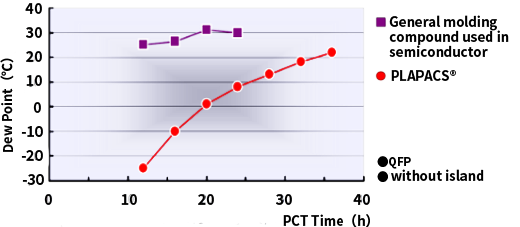

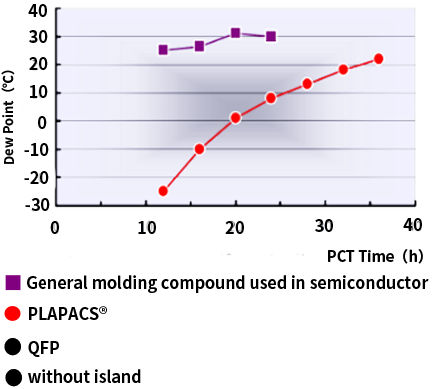

・High Humidity Resistance of PLAPACS®

By our unique epoxy resin combination, PLAPACS® resin has a higher moisture absorbency than general semiconductor resin and is impermeable to water.

Accordingly, you can use the package without dew condensation in the cavity even after certain moisture soak.

Application of PLAPACS®

- Digital still camera

- Digital video camera

- Surveillance camera

- On-vehicle camera

- MEMS

- Various sensors

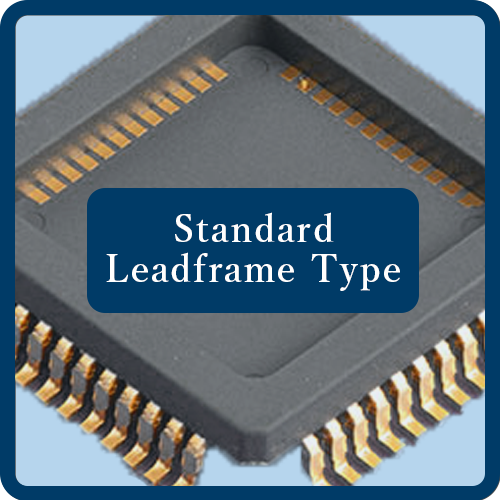

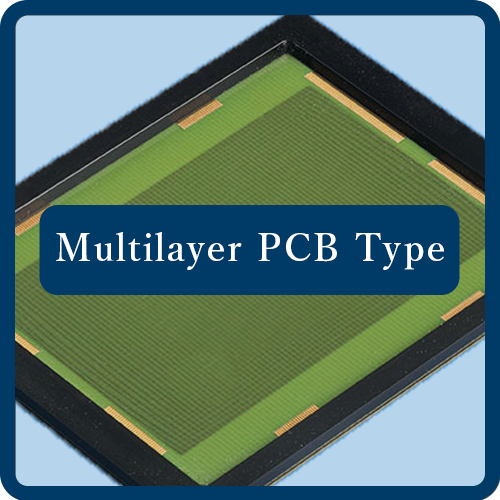

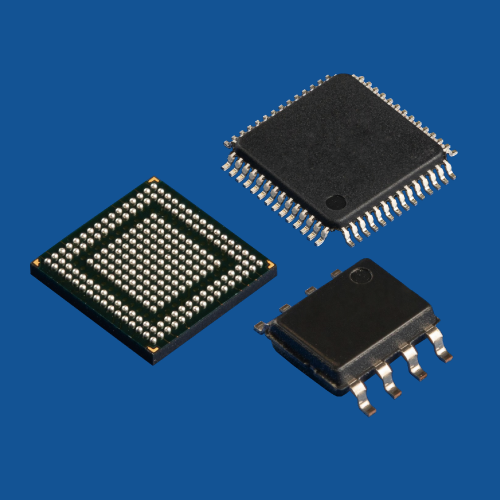

Product

We propose a hollow plastic package that has high moisture resistance and high dimensional accuracy by using our original resin compounding technology and our own mold processing technology.

Focusing on ultra-precision processing technology, we are developing four businesses: semiconductor assembly business, plastic molding business, equipment business, and automotive parts business. Our strength is that we can develop new products that combine each other's technologies and build highly efficient production lines using our unique technologies while developing our business independently.